Case Study

Leading the autonomous trucks market analysis, strategy development and pilot tests for a global distribution company.

CHALLENGE

One of the largest distribution companies in the world needed to understand how they can leverage the coming wave of autonomous trucks and build a competitive advantage.

SOLUTION

- Partnered with the CEO, COO and Head of Innovation to develop their framework for adoption of autonomous trucks, including market analysis, strategy development, solution design and pilot testing.

- Analyzed industry and customer ecosystems to generate a custom white paper. Content included high-potential applications, adoption timelines, relevant case studies, future KPIs, potential partners, competitive threats and market specific considerations across their global supply network.

- Curated a week long experience for our client and their customer at an industry leading conference, including a featured speaking slot. Also brokered high-end meetings, collaborative working sessions and an intimate high-end dinner that secured strategic relationships with technology providers, elected officials, government agencies, industry associations and venture capitalists.

- Designed and managed a Level 4 “driverless” autonomous trucks pilot test with a leading technology provider, including partner selection, agreement negotiation, test plan design and pilot management.

- Brokered a Level 1 Driver Assistive Truck Platooning (DATP) test with a leading technology provider, including partner selection, route selection and test plan design.

- Generated custom technology and deployment reports that guided the autonomous trucks strategy for our client as well as their customers, which include some of the largest brands in the world.

IMPACT

Client has positioned themselves as a trusted innovation partner for their customers, leading integration of autonomous trucks across the connected, smart and automated supply chain networks of the future.

View our services to see how GoodOps can help you build a competitive advantage by harnessing disruptive innovations such as autonomous trucks. Or send us an email at info@goodops.co to get started today.

New York Supply Chain Meetup

Recently the GoodOps co-founders were invited to present at The New York Supply Chain Meetup and share their innovative take on supply chain transformation consulting services. We had an incredible time being able to hear the different perspectives on supply chain innovation from experts across the industry. Each of the companies that presented are taking unique approaches to integrating advanced technologies, sustainability frameworks and agile operations in order to help brands build a competitive advantage through their supply chain:

- Ripe.io – Altering the trajectory of the food system through blockchain technology and the Internet of Things b.y designing a radically transparent digital food supply chain.

- Homer Logistics – A team of software developers, optimization experts, and operations leaders focusing on optimizing the last-mile, expedited shipping space.

- Chain.io – An experienced team of supply chain professionals who integrate logistics service providers, shippers, and software providers via a modern, secure, managed cloud.

- LuxLock – A SaaS Experience platform designed around the shopper to provide the ultimate high-touch shopping experiences with premium and luxury brands.

For anyone interested in innovative supply chain solutions, The New York Supply Chain Meetup is a diverse, knowledgeable and open community of leaders looking to connect and exchange insights. The event is open to all, whether you’re an expert or just an individual looking to learn more about the industry, which promotes a lively discussion and new perspectives on the topics at hand.

We want to thank Brian Laung Aoaeh and Lisa Morales-Hellebo, our friends and the co-founders of the event, for inviting us and giving us the opportunity to present our ideas and services to all those that attended. If you are interested in signing up for a future New York Supply Chain Meetup, please fill out the form below on their website, and welcome to the community!

The New York Supply Chain Meetup Signup Link

For more news and information regarding GoodOps, signup here for our “North Star” newsletter.

Press: GoodOps

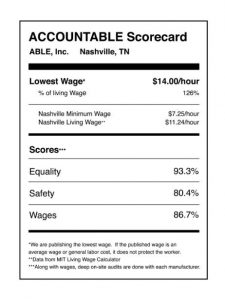

Congratulations to ABLE for launching a bold and disruptive campaign in fashion – publishing factory worker’s wages. Based on a rigorous supply chain audit performed by GoodOps, brands can evaluate their supply chains for potential risks. ABLE is a social enterprise focused on uplifting women out of intergenerational poverty. They are taking bold steps towards transparency to ensure their social impact marketing aligns with actual business practices. Their big dream is brands sharing their worker’s wages on the label of each garment the same way nutritional facts are labeled on food.

ABLE believes consumers will demand change once informed on the human cost of their purchases. ABLE wants brands to take the #PublishYourWages challenge to lift more women out of poverty globally. GoodOps is proud to have designed and led the sustainable supply chain audit for this powerful and ground-breaking initiative.

Learn more about their revolutionary campaign to change the fashion industry in Fast Company. #PublishYourWages #ShesWorthMore #livefashionable

De-risk your supply chain and strengthen your social / environmental impact through a custom supply chain audit – learn more about our services here: GoodOps.

Case Study

Launching a successful private label line for a leading Silicon Valley marketplace.

CHALLENGE

A Silicon Valley startup that was the leading content and commerce boutique shopping marketplace needed to solidify existing operations and better manage their purchasing vs. drop ship, all while expanding to launch their first ever private label line.

SOLUTION

- For existing operations, attended all industry trade shows, negotiated better pricing and payment terms with vendors, and educated them on our ecommerce packaging and delivery needs.

- Implemented a strategic decision making process for which “hot” items should be secured into inventory where supply was volatile at the vendor level.

- For launch of the private label line, designed both products and sourced a new supplier in China that could create initial prototypes as well as handle all replenishment needs and additional product lines.

- Due to limited startup funding, smartly kept costs down by managing the global process remotely and leveraging the resources of external partners.

IMPACT

Secured volume savings on basic items and ensured sufficient inventory for trending products. The private label items quickly became the number one and number two bestsellers on the website, surpassing the premiere branded items with lower prices and better margins.

View our services to see how GoodOps can help you build a competitive advantage through operating model transformation and new product innovation. Or send us an email at info@goodops.co to get started today.

Case Study

Designing and launching imports management for the ecommerce supply chain of one of the world’s largest retailers.

CHALLENGE

One of the world’s largest retailers needed to establish design, oversight and management of global imports for their ecommerce supply chain.

SOLUTION

- First ever to manage global ecommerce imports operations, overseeing more than $65M+ in shipments.

- Deeply analyzed existing processes and expanded opportunities for sourcing and purchasing.

- Critical improvements were obtained through innovative collaboration with the Direct Imports team at HQ, and onsite trips to Hong Kong with the buying team to educate suppliers at trade shows on ecommerce shipping and packaging.

- Led strategy for process and compliance, including factory conditions and housing for workers.

- Met with logistics partners at the Port of Shenzhen, China (the world’s third largest container port) to expand communications and information sharing.

- Partnered with buying, planning and logistics teams across brick-and-mortar and ecommerce divisions, obtaining data and creating new essential visibility tools that were used to track inbound orders and open-to-buy commitments.

- Designed training programs and tools for all departments and vendors, launched integrated systems to reduce risk, and created a global dashboard to manage KPIs.

IMPACT

Designed, managed and improved the ecommerce supply chain and operations for the world’s largest company. Developed innovative strategies that opened new modes of doing global business.

View our services to see how GoodOps can help you build a competitive advantage by designing, deploying and scaling ecommerce operations. Or send us an email at info@goodops.co to get started today.

Case Study

Leading the peak season, holiday ecommerce operations inbound supply chain management for one of the world’s largest retailers.

CHALLENGE

One of the world’s largest retailers needed exceptional management and oversight of inbound supply chain management to avoid shipping delays, increase efficiencies and reduce risks in their holiday ecommerce operations.

SOLUTION

- Oversaw a team of 17 direct reports 6 months prior to holiday season to ensure all necessary processes, reports and training were implemented.

- Once the critical plan and strategy was in place, the team began operating at an accelerated rate in October, working daily to manage all international and domestic shipments and ensure goods were on track to deliver in time.

- By November, designed and led the first ever 7 days a week, cross-functional, in person “swat” team meeting that included the entire C-suite, monitoring each aspect of the global supply chain and remedying any errors along the way for fast resolution.

- Created and managed a separate team to handle all critical ‘tickets’ issued by 9am each day where a strategy for resolution was expected by noon the same day.

- Tracked and escalated any unresolved challenges to address at the following day’s meeting until closed.

IMPACT

Millions of dollars of lost sales were saved due to advanced visibility. Hyper-detailed and collaborative management of the inbound supply chain allowed for swift action when unforeseen issues arose. The overall result extended to better interdepartmental relationships, improved business operations and greater customer satisfaction.

View our services to see how GoodOps can help you build a competitive advantage through strategic and dynamic management of holiday ecommerce operations. Or send us an email at info@goodops.co to get started today.

Case Study

Reducing landed cost by 3-5% for one of the largest regional warehouse club chains.

CHALLENGE

One of the largest operators of membership warehouse clubs in Central America and the Caribbean needed to reduce the landed cost for multiple items exported from the USA and China, shipping to 24 stores in 14 countries.

SOLUTION

- Analyzed the extended supply chain and applied a multi-strategy approach to accurately assess each product’s landed cost profitability margin.

- Calculated each item’s cost per cube to ensure shipping cost did not exceed 10% of cost of goods sold (COGS).

- Researched correct tariff classification per product, by country, for current export/import duties and attributed costs appropriately.

- Determined carrier rates and time in transit of various container and less than container load (LCL) trade routes to determine optimal allocation.

- Products were then divided between mixed containers and LCL shipments, based on shipping cost, time in transit and sales demand.

IMPACT

Ascertained the best method of shipping goods through comprehensive analysis at the item level, reducing landed cost on average by 3-5% for every shipment.

View our services to see how GoodOps can help you build a competitive advantage through more efficient global logistics and improved earnings. Or send us an email at info@goodops.co to get started today.

Case Study

Managing global inventory and mixed container exports across 14 countries.

CHALLENGE

One of the largest operators of membership warehouse clubs in Central America and the Caribbean needed to manage retail buying, inventory planning and global logistics for three product categories across 24 clubs in 14 countries.

SOLUTION

- Buying entailed attending international trade shows to select products and negotiate directly with vendors.

- Optimized and managed inventory planning for 24 clubs in 14 countries on JD Edwards ERP software, to ensure the right product and the right quantity, arrived on time.

- Managed global logistics cost and time in transit at the product level for each store; ensuring the best trade options were used by analyzing 10 weeks of inventory levels and determining when to replenish stock and factor in seasonality, spikes and trade routes.

IMPACT

Effective and efficient buying, planning and logistics led to a reduction in landed cost, an increase in profit margin and fewer out of stock situations.

View our services to see how GoodOps can help you build a competitive advantage through more efficient global logistics and improved earnings. Or send us an email at info@goodops.co to get started today.

Case Study

Optimizing global sourcing for one of the world’s leading ecommerce flash sales companies.

CHALLENGE

A leading global ecommerce flash sales company was struggling to find an efficient and profitable way to import a variety of eclectic, single unit, ‘market finds’ from shops and outdoor bazaars around the world – including Morocco, Belgium and India.

SOLUTION

- An innovative new “tagging” process was created which gave the buyer freedom to source creatively, and profitably for the first time, from street markets. This included matching the product through a two-tagging process that reduced the complexity of picking up goods and getting them to a freight forwarder.

- By sourcing and onboarding a local export agent, all the necessary import and materials documents were obtained in advance.

- Navigated the complexity of US Customs to register the company as the Importer of Record, ensuring efficiency and compliance for the future rapid growth of the company.

- The improved process transformed an inefficient, costly global sourcing operation, finally allowing sufficient time to register for appropriate licenses needed to clear customs with no delays, fees or penalties.

IMPACT

Our never done before tagging process solved a critical sourcing need, making the “market finds” buying process profitable for the first time, with product arriving to the fulfillment center on time and accurately accounted for. In addition, the new import processes and logistics partnerships created drove the scalability of future procurement efforts.

View our services to see how GoodOps can help you build a competitive advantage by transforming your global sourcing. Or send us an email at info@goodops.co to get started today.

Case Study

Launching a global innovation program for one of the world’s largest supply chain solutions providers.

CHALLENGE

One of the largest global distribution companies needed to more effectively address accelerating customer demands, technology trends and disruptive competitors.

SOLUTION

- Partnered with the CEO, COO and newly appointed Head of Innovation to design and launch a global supply chain innovation program. Key activities included market and trends analysis, strategy development, innovation portfolio management, solution design and pilot testing.

- Analyzed industry and customer ecosystems to identify the most relevant, immediate, disruptive and actionable technology trends.

- Prepared and educated client on priority trends through a series of customized white papers. This included exploration of autonomous trucks, artificial intelligence, blockchain, the warehouse of the future, and the wider industry shift towards dynamic distribution models. Content included high-potential applications, adoption timelines, relevant case studies, future KPIs, potential providers and partners, competitive threats and global/market specific deployment considerations.

- Designed and facilitated workshops with senior executives and rising leaders across markets and functions to develop actionable solutions.

- Curated a week long experience for our client and their customer at an industry leading conference. This included securing a featured speaking slot, brokering high-end meetings, designing a collaborative working session with conference attendees, and hosting an intimate dinner that secured strategic relationships with technology providers, elected officials, government agencies, industry associations and venture capitalists.

- Led pilot tests for priority technologies, including business case development, provider selection, test plan design, negotiation of partnership agreements and generation of post-test reports with detailed deployment recommendations.

IMPACT

- Client has successfully deployed pilot tests and positioned themselves as a trusted partner for the future of digitally-connected customer supply networks, leading the design and integration of critical technologies, products and services.

View our services to see how GoodOps can help you build a competitive advantage by launching and scaling a supply chain innovation program. Or send us an email at info@goodops.co to get started today.