Why A Sustainable Supply Chain?

The supply chain revolution is here and companies must transform to become socially and environmentally responsible.

Brands face increased pressure from purpose-driven customers, disruptive competitors, concerned shareholders and distressed suppliers. In order to survive – be it a Fortune 500 or a high-growth e-commerce startup – companies must undergo a transformation in how they source, produce and deliver their products and services.

Supply chain sustainability is the backbone and competitive advantage of the world’s most successful companies.

Companies can no longer rely on incremental impact, legacy systems and traditional corporate responsibility. Sustainability with integrity is hard; it requires a clear vision for the future, an understanding of complex ecosystems, and the agile deployment of interconnected strategies, systems and capabilities.

GoodOps makes transformation easy by designing innovative strategies to implement custom sustainability frameworks.

We are the compass for our clients, guiding them to stay one step ahead during a time of accelerating change. We realign and digitally connect supply chain networks across brand values, embedding new ways of thinking and collaborating from the c-suite to the frontline across partners. In parallel, we explore and leverage advanced technologies to explore the best way to make the desired impact on the resources and workers in the supply chain. We empower companies to become strong stewards of our planet and people so they can feel confident sharing an authentic journey with their customers.

Companies that transform into sustainable supply chains will improve profit, streamline operations and mitigate risk.

Customers choose purpose-driven brands over competitors, the most talented employees want to work for them and investors seek their limited risk profiles. End-to-end visibility, from raw material to finished goods, drives accountability and agility, helping brands become true partners in their supply network. Savings and valuable growth opportunities are realized across the extended value chain. And higher quality, socially responsible products differentiate their offering and justify premium pricing.

The key to success is properly prioritizing, organizing and resourcing complex sustainability initiatives.

All companies know they must implement social and environmental initiatives, but many times, this requires sourcing from new suppliers, adopting alternative materials and restructuring supplier contracts; the hard part is knowing where to start and how to execute. In every engagement, we design custom, multi-disciplinary teams augmented by networks of global experts with the necessary experience, skills and pragmatism to ensure results. Applying universal principles, market specific nuance and an agile approach, we scale what works.

We believe transforming supply chains is the fastest way to positively impact the world.

The 17 UN Sustainable Development Goals is a powerful blueprint for brands. Goal #5: Gender Equality, #8: Decent Work and Economic Growth, #10: Reduced Inequalities, #12: Responsible Consumption and Production, #14: Life Below Water, #15: Life on Land and #17: Partnerships for the Goals are just some of the goals brands can begin to focus on today. By simplifying complex sustainability initiatives, GoodOps helps companies achieve the impact they want to have in the world in a meaningful way.

View our services to see how GoodOps helps brands and startups build a competitive advantage through supply chain sustainability. Or send us an email at info@goodops.co to get started today.

Ethical Supply Chains

At GoodOps, we believe transforming global supply chains to meaningfully address environmental and social issues is the fastest way to change the world. But systemic change is complex and a range of multidimensional approaches are critical to ensure success. We bring diverse groups of supply chain leaders together for intimate salons in order to achieve this goal. Every salon explores the strategies, models and technologies they are applying to create a more sustainable future. Last week, we gathered 20 leaders from Fortune 500s, high-growth startups, international organizations and academic institutions across a range of industries and regions. Our focus was the rise of ethical supply chains.

It is critical that companies improve the lives of their workers and communities through the development of more ethical supply chains. It is estimated that 80% of world trade and 60% of production runs through multinational company supply chains. In terms of global workforce, more than 20% have jobs in a global supply chain. Drilling down into 50 of the world’s largest companies, it is estimated that they directly employ just 6% of the workers in their supply chain. The remaining 94% of their “hidden” workforce is at least 116 million people. Within those jobs, over 50% are estimated to be exploitative with poor conditions, including long hours, dangerous working conditions, forced labor, low or poverty wages and informal work.

Broadly, this group of supply chain leaders who are setting the future of business, culture and government expressed that we may have reached a potential tipping point. A tipping point is defined as a series of small changes or incidents that become significant enough to cause a larger, more important change. The leaders gathered shared perspectives that pointed to a convergence of key trends that were accelerating the rate of change. These trends included increasingly conscious and demanding consumers, shifting executive mindsets, stringent regulations with criminal prosecution of bad actors and accelerated supply chain digitization efforts.

Below is a summary of what the leaders highlighted across these key trends:

- Companies will no longer be able to avoid responsibility for their end-to-end supply chain networks. Deflecting criticism or risk by saying abuses occurred outside their direct employee base will fall flat and fail to satisfy conscious consumers, employees and investors. Proactive companies are already going beyond 1st tier suppliers to predict and address social issues from materials sourcing through final mile delivery. Most critically, they are directly engaging workers and performing onsite audits to avoid the risks inherent in company or supplier self-reporting where there is no 3rd party verification.

- Consumers are arguably the most powerful lever in driving adoption of ethical supply chains. They are putting their money where their mouth is by purchasing responsibly made products as well as demanding more accountability from the brands they support. Companies will thrive by reducing information friction and helping consumers make ethical purchasing choices. The leaders also predicted a rise in employee movements, with consumers no longer checking their personal beliefs at the door when they come to work.

- Governments will establish criminal consequences for brands who allow illegal activity in their supply chain, especially when it comes to modern day slave labor. It was predicted that governments may increasingly hold not just companies but executives themselves responsible for worker wages, equality and safety. In addition, incentives must be created for ethical companies to accelerate compliance.

- Investors must more consistently check and confirm that the brands they invest in are ethically sourcing and producing their products and services. They must make a commitment to investing in companies that are rigorously audited and disciplined in their approach. It was predicted that the next 2 years will see a rise in mass investment screening tools that will identify shareholder activism opportunities and reallocate portfolios to avoid negative impact or support specific causes they care about. There will be a rise in funds that address supply chain sustainability in particular.

- Technology solutions are the key to giving companies end-to-end visibility and scaling ethical supply chains. Technology platforms and tools focused on worker empowerment, product traceability, ethical sourcing and risk mitigation will become a core component of any technology stack. The resulting data and insights will be especially beneficial in supporting CEO and brand activism as well as consumer movements.

Companies that wish to lead in the future must take immediate action. First, analyze your industry and extended value chain to identify the greatest risks and opportunities for impact. Next, collaborate with value chain stakeholders to create an integrated roadmap for sustainable change across your strategies, systems, processes and culture. With a clear vision for the future, you can build the necessary capabilities, teams and partnerships to ensure success.

Do you think we have reached a tipping point for ethical supply chains? Want to get involved in the work GoodOps is doing? We’d love to hear from you.

- View our services to see how we can help you build competitive advantage through an ethical end-to-end global supply chain.

- Send us an email at info@goodops.co to get started today or join a future salon.

- Sign up for our “North Star” newsletter to get the most important news, insights and profiles on supply chain transformation.

United Nations SDGs

The United Nations Sustainable Development Goals (SDGs) are an interconnected set of 17 goals and 169 targets that industry leaders are using to drive sustainability efforts. The SDGs seek to protect the planet and improve the lives of every human by 2030. They are a detailed and easy to adopt framework that companies such as Unilever, TOMs and GlaxoSmithKline use to achieve their own strategic priorities while simultaneously addressing more stringent regulations, global pacts and consumer activism. These companies are seeing higher returns on investment, faster brand growth and long-term shareholder value. And the wider economic benefit is potentially massive, as the Business & Sustainable Development Commission projects that embracing the SDGs could generate US $12 trillion of new business value a year – equivalent to 10% of the global GDP forecast by 2030.

Developing a holistic supply chain sustainability strategy using the United Nations SDGs will inspire, attract and retain the customer and employee of the future. Sustainability is no longer a niche business consideration. Studies show that people increasingly expect companies to address social and environmental issues in a meaningful, measurable and transparent way. In a world where people are purchasing goods and making career choices based on this expectation, companies must properly address the impact of their daily operations. This requires moving beyond siloed corporate social responsibility departments and ad hoc social marketing programs. The SDGs are one of the most effective and comprehensive frameworks that can help companies meet rising expectations while improving business performance.

The 17 SDGs are:

- No Poverty

- Zero Hunger

- Good Health and Well-Being

- Quality Education

- Gender Inequality

- Clean Water and Sanitation

- Affordable and Clean Energy

- Decent Work and Economic Growth

- Industry, Innovation and Infrastructure

- Reduced Inequalities

- Sustainable Cities and Communities

- Responsible Consumption and Production

- Climate Action

- Life Below Water

- Life On Land

- Peace, Justice and Strong Institutions

- Partnerships for The Goals

Companies that wish to lead in the future should take immediate and strategic action to integrate the SDGs across their supply chain networks. By proactively implementing the SDGs across the supply chain – from how they source raw materials to how they deliver finished products to customers – companies can spark customer loyalty, improve productivity, mitigate risk and drive business growth. Most importantly, they can establish a competitive advantage before sustainability becomes a common and core part of every business.

View our services to see how GoodOps can help you build a sustainable competitive advantage by aligning your supply chain network with the UN SDGs. Or send us an email at info@goodops.co to get started today.

Press: GoodOps

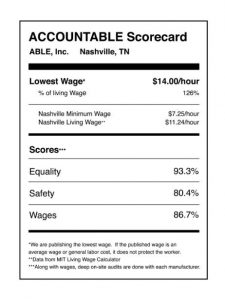

Congratulations to ABLE for launching a bold and disruptive campaign in fashion – publishing factory worker’s wages. Based on a rigorous supply chain audit performed by GoodOps, brands can evaluate their supply chains for potential risks. ABLE is a social enterprise focused on uplifting women out of intergenerational poverty. They are taking bold steps towards transparency to ensure their social impact marketing aligns with actual business practices. Their big dream is brands sharing their worker’s wages on the label of each garment the same way nutritional facts are labeled on food.

ABLE believes consumers will demand change once informed on the human cost of their purchases. ABLE wants brands to take the #PublishYourWages challenge to lift more women out of poverty globally. GoodOps is proud to have designed and led the sustainable supply chain audit for this powerful and ground-breaking initiative.

Learn more about their revolutionary campaign to change the fashion industry in Fast Company. #PublishYourWages #ShesWorthMore #livefashionable

De-risk your supply chain and strengthen your social / environmental impact through a custom supply chain audit – learn more about our services here: GoodOps.

Transforming Food Quality

The age of wasted produce has a sustainable light at the end of the tunnel. Apeel, a company founded on the idea of reducing produce waste in grocery stores and supermarkets around the world, is transforming food quality by increasing the lifespan of shelf items. By using a harmless plant-based coating, it can extend the lifetime on a shelf from days to even weeks. U.S retailers lose up to $18 billion annually on lost produce that’s thrown away. However, Apeel is looking to cut this number drastically for the years to come. For example, Apeel reduced produce waste by 60% during an initial four month pilot with a leading U.S. regional grocery chain. Apeel executives have stated they plan to grow gradually, despite so much interest from distributors nationwide. The company has also hinted at aiming to stay just within the U.S. However, talks with Peruvian distributors may have the company heading in a more globalized effort in in the future. Food companies must innovate to meet future needs of both consumers and the environment. Where will technology lead us into the future with food sustainability? Will this be a key element aiding global hunger by reducing waste?

Want to learn more?

- Read the original Fast Company article.

- See our case study on how we launched the innovation program for a global food supply chain provider that explored advanced technologies and operating methods.

- Sign up for our “North Star” newsletter to get the most important news, insights and profiles on supply chain transformation.

Apple Pushes Sustainability

The technology juggernaut, Apple, is taking a step towards a cleaner, more energy renewable future. The company stated it would invest $300 million through key suppliers to make their supply chain more efficient and cleaner. Furthermore, the project will bring in over 1 GW of renewable energy. This investment is on top of its 25 renewable energy projects it currently runs. As Apple pushes sustainability, it hopefully will encourage other large retailers to begin investing in efficient supply chains. The sustainability movement is in line with the UN’s sustainable development goals, pertaining to affordable and clean energy. Finally, with a target of 1.4 GW of capacity, a project like this among its key suppliers is a step to a better future. Will other companies begin to follow suit? What are ways smaller corporations can invest in sustainability without a budget as large as Apple?

Want to learn more?

- Read the original Energy Digital article here.

- See our researched op-ed on how altering one’s supply chain to be more sustainable can lead to a more holistic competitive advantage long-term..

- Sign up for our “North Star” newsletter to get the most important news, insights and profiles on supply chain transformation.

NextGen Cup Challange

Companies around the world are rapidly evolving to meet consumer standards regarding environmental sustainability. With surmounting evidence proving the issue of global warming, industries are beginning to look differently at their supply chains. Two competitors in the QSR world, McDonald’s and Starbucks, are actually teaming up to redesign their cups to be more eco-friendly. The leading initiative is called the NextGen Cup Challenge, and is an unprecedented attempt to reduce a company’s ecological footprint and reduce global waste. The two QSR giants are even encouraging other companies to join in on their quest to a better cup. Within three years, the companies are working together to produce a cup that is completely recyclable and compostable. Along with their new and improved cup, the companies are also planning to incorporate a new lid and straw. Ultimately, these will all reduce plastic, be totally recyclable, and still be functional to the consumer. What steps beyond cups will companies make to promote sustainability? Are McDonald’s and Starbucks ushering in a new era of QSR sustainability?

Want to learn more?

- Read the original Fast Company article.

- See our case study on how we launched the innovation program for a global food supply chain provider that explored advanced technologies and operating methods.

- Sign up for our “North Star” newsletter to get the most important news, insights and profiles on supply chain transformation.

Supply Chain Sustainability

Supply chain sustainability is an essential component of all business today and every company must consider their environmental and social impact a top priority. The key drivers pushing this momentum forward include risk mitigation, compliance requirements and consumer activism, all of which will continue to increase due to accelerated globalization and technology. Companies that authentically and transparently incorporate sustainability throughout their supply networks will spark customer loyalty and drive business growth while also improving employee productivity, reducing costs and mitigating risk.

Companies must holistically embed sustainability across their entire supply network. After many high-profile examples of damaged brand reputation and profits due to poor working conditions, resource exploitation and corrupt management, companies have woken up to the responsibility expected of them. In a world where people are purchasing goods and making career choices based on this expectation, companies can no longer rely on siloed corporate social responsibility departments or ad hoc social marketing programs; they must embed sustainability across their extended supply chain to set a strong foundation for success.

Existing frameworks deployed by industry leaders can help companies more easily design and deploy their own supply chain sustainability strategy. In the past, companies had to start from scratch when creating their approach to supply chain sustainability, with little insight into industry best-practices and benchmarks. However, leading brands, global institutions and industry associations have made critical early strides in establishing actionable frameworks, such as The United Nations Sustainable Development Goals (SDGs), The Paris Agreement, the Sustainable Apparel Coalition (SAC), the Carbon Disclosure Project (CDP), and The Ceres Roadmap for Sustainability. The common thread across the most effective frameworks is an integrated consideration of environmental, social and governance (ESG) practices.

The key to success is defining an approach to environmental, social and governance practices across the supply network that also drives competitive advantage. From how they sourcing raw materials to how they delivering finished products to customers, companies can reduce costs through a focus on practices such as waste reduction and more efficient usage of energy and water. Smart companies leverage those activities to differentiate their offering and create a uniquely compelling brand experience for customers and employees. Establishing interconnected governance practices, such as sustainability targets tied to performance management and pay for executive leadership, ensures accountability and progress.

Companies that wish to lead in the future must take immediate and strategic action on supply chain sustainability. Doing good isn’t just about feeling good; organizations rating highly in their approach to environmental, social and governance practices outperform the market in medium and long range terms. With rising proof around the business case for sustainability, the time to act is now. Early movers will establish a competitive advantage before sustainability becomes a common and core part of every business.

View our services to see how GoodOps can help you integrate supply chain sustainability and build a competitive advantage. Or send us an email at info@goodops.co to get started today.

Case Study

Creating the sustainable fashion supply chain framework for a high-growth brand.

CHALLENGE

A high-growth, socially responsible fashion brand with global sourcing and manufacturing needed to verify their impact claims and establish a supply chain sustainability framework.

SOLUTION

- Built a database of over 400 leading sustainability codes, standards, marks and associations across all industries and regions.

- Established an integrated set of sustainable fashion supply chain industry benchmarks that addressed the social and environmental considerations at each stage of our client’s extended value chain. This included the farms their supplier’s used to production sites across Africa, Central America, South America and the United States.

- Analyzed our client’s extended value chain to prioritize sustainability opportunities and challenges, and assessed the impact of change on the company strategy, operations and bottom line.

- Designed a robust assessment framework and scoring system that would give fashion companies a true sense of their social, environmental and governance practices and impact across their supply chain.

- Led rigorous and exhaustive on-the-ground audits with suppliers in Ethiopia, including the collection and examination of financial statements, utility bills, supplier receipts, employee handbooks, safety reports and more, as well as performing one-on-one, confidential interviews with factory employees and detailed anonymous employee surveys.

- Ensured accountability and progress by identifying weaknesses, collaboratively developing actionable improvement plans with their suppliers, and negotiating incentives for compliance.

- Supported extended value chain conversations with government agencies, training centers and regional associations to ensure higher quality raw materials, reduced cost of goods, market expansion opportunities and more skilled labor.

IMPACT

With a radically transparent and verified sense of all their sustainability challenges, the company renegotiated supplier contracts and collaborated on improvement plans that reduced risk across their extended supply chain.

View our services to see how GoodOps can help build a competitive advantage by integrating sustainability from suppliers to customer delivery. Or send us an email at info@goodops.co to get started today.